Youtube video link

www.youtube.com/watch?v=O6WfLJvpmsE

www.youtube.com/watch?v=46BjNcuK9Wc&t=4s

www.youtube.com/watch?v=Fj0f0W3zWNU&t=11s

www.youtube.com/watch?v=QjCOGTEWlUM

www.youtube.com/watch?v=AZDyCQfF1ok

www.youtube.com/watch?v=xs7_WVZNmio

www.youtube.com/watch?v=Fj0f0W3zWNU

www.youtube.com/watch?v=xUMTIBqfTOs

www.youtube.com/watch?v=ZJLTWVv25vg

www.youtube.com/watch?v=GIDGHk9iH3k

https://youtu.be/yemJI6vWGKw

WHOLE MACHINE FEATURES

1. Automatic carton box folder gluer include vacuum absorb feeder unit , fold glue unit and counter amending output unit.

2. Digital display control, PLC touch screen computerized setting box size, Fault alarm display system, Avoid worker wrong operation, Easy to operate and use,

3. Double frequency synchronous run, It has simple, fast, reliable and accurate operation mode,

4. Automatic feeding, automatic folding and gluing, automatic counter, automatic stack and output,

5. Remote control within 100 meters, control the machine machine on/off, main machine speed up/down, vacuum fan on/off, feeding on/off , emergency stop, left-right arm adjust, glue tank movement.

6. Whole machine have the order save system, one key order change, Average speed 150m/minute , High speed and energy saving, Save labor cost.

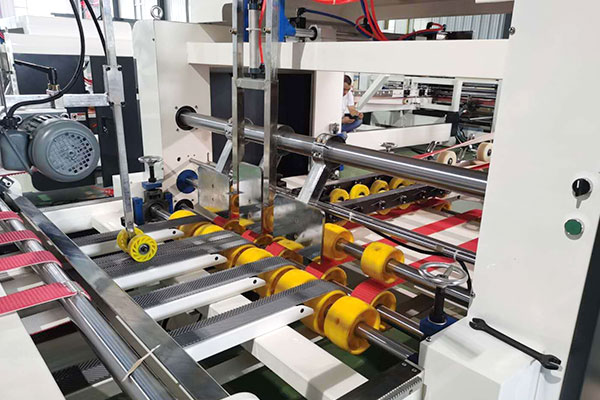

FEEDER UNIT

1. Adopt belt type vacuum absorb feeding.

2. Adopt the high-grade electromagnetic clutch and electromagnetic brake system, so that the paper feeding unit can be independently controlled, simple and reliable operation

3. Feeding roller height is adjustable, The bottom feeding roller made of polyurethane material, wear resistance, good elasticity, Soft texture and not damage the cardboard when do pre-creaser. Suitable for cardboard thickness from 2-8mm.

4. Feeding unit pre-creaser roller combined with the folder unit , Frequency control motor speed, speed 0-150m/ minute

5. Equipped with double electric eyes to detect cardboard delivery, Feed back to PLC system, Make sure the cardboard delivery is correct

6. The left-right baffle of the feeder unit can be adjust automatically, Back baffle manual movement.(can choose auto adjust)

GLUE AND FOLD UNIT

1. The main motor adopts frequency conversion speed regulation system, noiseless, Flexible control speed,

Separate fan cooling

2. Adopt imported high friction belt to delivery cardboard, auto fold cardboard.

3. adopt the Stainless glue wheel, Glue Amount evenly ,and save glue.

4. Fold unit with two unit creaser, pre-creaser and creaser, correct the cardboard creaser and do good folding.

5. fold unit inside have Two rows of adjustable fold plate, precision fold.

6. All the delivery wheel adopt the nylon material. Noiseless, Strong and durable

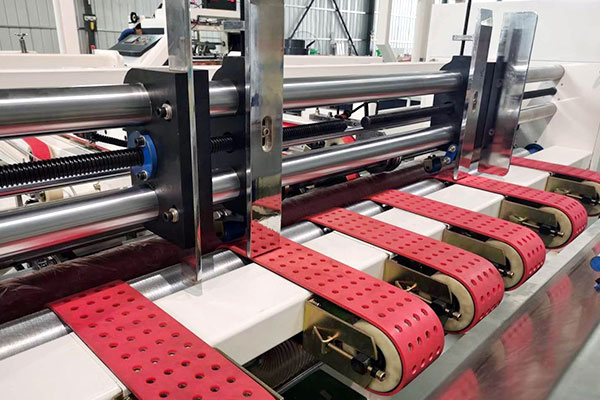

COUNTER AMENDING AND OUTPUT UNIT

1. Automatic stack and neat output, Top pressure wheel position is adjustable, so that the carton glue finishing well.

2. Counter unit motor adopt frequency conversion speed regulation system, speed adjustable. Stable and reliable startup

3. With belt delivery the carton. Neat stack. Speed 0-200m/minute

4. The delivery wheel of the counter unit have the speed regulation device, with the speed regulation device and the Flapping plate to do carton amending, The carton shape finishing well.

5. Air cylinder control the counter and output, PLC electric control, The action is reliable, accurate and fast

6. Adopt PLC touch screen control counter, bundle quantity, cylinder movement time. Easy operation. Can change data without stop the machine.

7. Output part adopt bottom delivery belt and top pressure belt Synchronous output. Make sure carton box glue well and neat output.

TECHNICAL PARAMETER

| Normal size | Jumbo size | ||||

| MODEL | WX-1224 | WX-1228 | WX-1628 | WX-1640 | WX-2245 |

| Max board size | 1200×2400 | 1200×2800 | 1600×2800 | 1600×4000 | 2200X4500 |

| Min board size | 180×450 | 280×700 | 300×800 | 600×3000 | 900X3000 |

Note: Special requirement, Can be customized according to customer needs