Youtube video link

www.youtube.com/watch?v=dlKrERclhPI&t=2s

www.youtube.com/watch?v=BoeojS4BKkA

1. SPECIFICATION

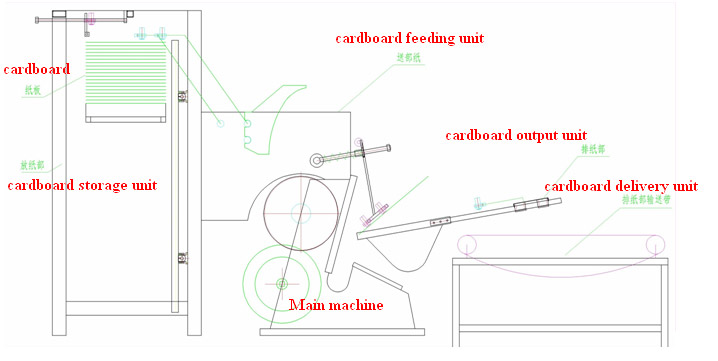

The machine have 6 section:

Main machine(die cutting creasing machine), cardboard storage unit, cardboard feeding unit, cardboard output unit, cardboard delivery unit. Air compressor(customer prepare)

1. The cardboard storage unit is mainly used to store cardboard and adjust the position of cardboard.

2. The cardboard feeder unit is used to feed cardboard inside die cutting creasing machine and correct the position.

3. The cardboard output unit take cardboard to the delivery belt.

4. The cardboard delivery unit send cardboard out

5. The compressor supply the air to the machine.

PARAMETER

| 1.Max cardboard: | 1500X 1000 mm | 1200X 800 mm |

| 2.Min cardboard: | 410 X 400mm | 410 X 400mm |

| 3.Feeding precision: | ±0.75 mm | ±0.75 mm |

| 4.Working speed: | 18±2 /minute | 20±2 /minute |

MATERIAL

1. The machine body and frame are connected with 100X50 square pipe, which is reasonable in structure and durable.

2. Most transmission shafts adopt linear optical axis.

3. The gear is quenched with 45# steel and wears well.

4. Suction nozzle using flat die-cutting machine suction nozzle, suction, smooth paper.

5. The vacuum air pump adopts 140B oil-free vacuum pump and 16mm air pipe to ensure the normal operation of suction nozzle.

6 suction nozzle action time control valve using the factory’s latest development of adjustable time CAM control valve, reasonable structure, durable, not afraid of dust, large ventilation, greatly beyond the rotary air valve (feed paper flying head used) performance, to fill the rotary air valve defects

CHARACTERISTIC

1. Speed same with die cutting creasing machine

2. Simple structure and easy to adjust.

3. Electronic counter to count

4. Adopt electric bell, when the equipment starts up to ring warning, improve the safety warning.

5. Safety operation and save labor