Youtube Video Link

www.youtube.com/watch?v=w92fh7PlOpM&t=7s

www.youtube.com/watch?v=rzdncFtLKEc

www.youtube.com/watch?v=27xzBHP5N7A&t=2s

www.youtube.com/watch?v=R1BbnxnuV0A

www.youtube.com/watch?v=6xvJ-R8w60Y

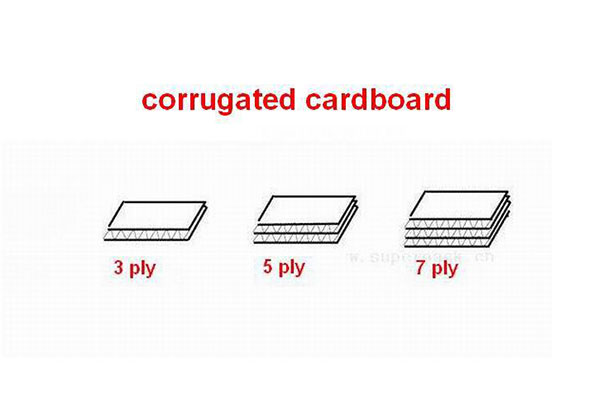

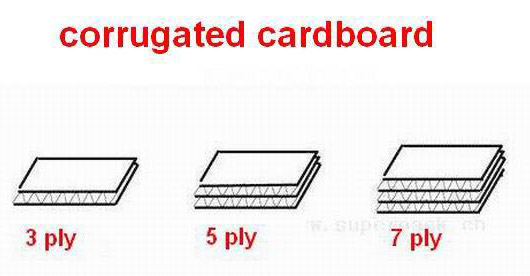

corrugated cardboard production line include the following machines

| MACHINE NAME | 3 ply corrugated line | 5 ply corrugated line | 7 ply corrugated line |

| mill roll stand machine | 3 sets | 5 sets | 7 sets |

| pre-heater machine | 2 sets | 4 sets | 6 sets |

| single facer machine | 1 set | 2 set | 3 set |

| Paper delivery bridge | 1 set | 1 set | 1 set |

| duplex pre-heater | 1 set | ||

| Triplex pre-heater | 1 set | ||

| Four-layer pre-heater | 1 set | ||

| Single gluing machine | 1 set | ||

| Double gluing machine | 1 set | ||

| Triplex gluing machine | 1 set | ||

| double facer mahcine | 1 set | 1 set | 1 set |

| thin blade slitter scorer machine | 1 set | 1 set | 1 set |

| NC cut off machine | 1 set | 1 set | 1 set |

| delivery stacker machine | 1set | 1set | 1set |

| Glue making machine | 1 set | 1 set | 1 set |

Corrugated cardboard line Machine working principle

The paper roll fed by the mill roll stand. After heated and moisture adjusted by the pre-heater machine, core paper will go to the single facer, corrugated by roller, and gluing together with top paper to become single faced corrugated paperboard. Then conveyed through the bridge, pre-heated again by pre-heater machine, after glued by gluing machine, jointed by the double facer machine. And come out the corrugated cardboard board

The corrugated cardboard After slitting and scoring by thin blade slitter scorer and transverse cutting by NC cuter machine, corrugated board with different sizes are produced. Finally, these different size corrugating board will be stacked, calculated and then sent out by the stacker

Parameters Requirements In Production Line

Production line speed test paper should meet the following requirements:(the surface temperature of the equipment is not less than 172℃)

1. Paper rating of not less than B grade; Paper moisture content of about:11%±2%

2. Top paper index; 100g/㎡–180g/㎡; Ring crush index(N.m/g)≥8; (Water containing8-10%)

Core paper index 80g/㎡–160g/㎡; Ring crush index(N.m/g)≥5.5; (Water containing8-10%)

Inner paper index 90g/㎡–160g/㎡; Ring crush index(N.m/g)≥6; (Water containing8-10%)

3. Flute-type combination:A 、C、B、E(as customers’ requirement).

3. Steam the necessary requirements:

Amount of steam 1500—2000Kg/H (3ply line); 3000-4000KG(5 ply line)

Max pressure: 1.2Mpa; Common pressure: 0.8-1.1Mpa

4. Equipment installed total power: 150-250KW.

Machine size and speed

| MODEL | WJ-1400-3/5/7 | WJ-1600-3/5/7 | WJ-1800-3/5/7 | WJ-2000-3/5/7 | WJ-2200-3/5/7 | WJ-2500-3/5/7 |

| SIZE(MM) | 1400 | 1600 | 1800 | 2000 | 2200 | 2500 |

| SPEED | 70-250M/MINUTE | |||||